DOT Inspections Explained: A Complete Guide for 2025

More than 3.3 million roadside inspections are conducted annually by the FMCSA and state partners. In 2024 alone, 21.6% of vehicles and 6.7% of drivers were placed out of service. Understanding what inspectors look for and how each type of DOT inspection works, is key to keeping your fleet on the road and in compliance.

This guide breaks down every inspection level and what you need to track, prepare, and prevent to avoid violations and costly downtime.

What Is a DOT Inspection?

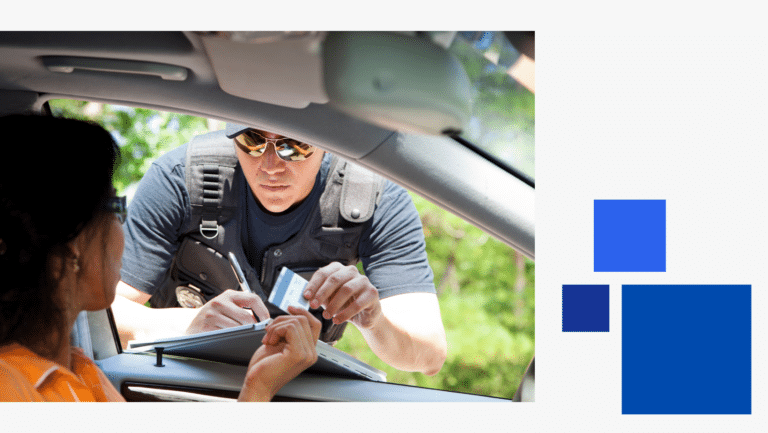

A DOT (Department of Transportation) inspection is a comprehensive safety review performed by a certified inspector to ensure that both the commercial motor vehicle (CMV) and the driver fully comply with federal safety regulations. These inspections are a key part of the FMCSA’s efforts to reduce accidents and improve roadway safety.

Inspections can be conducted at a various locations, such as weigh stations, border checkpoints, bus terminals, a carrier’s terminal, or when a law enforcement official stops a CMV.

The 7 Levels of DOT Inspections – Explained

The Federal Motor Carrier Safety Administration (FMCSA) defines seven main levels of DOT inspections. Each serves a different purpose and varies in depth.

Level I – North American Standard Inspection

The most comprehensive and commonly performed inspection. This inspection involves a complete check of both the driver and vehicle, including:

- Driver checks:

- Driver’s license

- Medical Examiner’s Certificate

- Skill Performance Evaluation (SPE) Certificate (if applicable)

- Drug/alcohol indications

- Hours of service (HOS) and duty status

- Seat belt usage

- Vehicle inspection reports

- Vehicle checks:

- Brake systems

- Cargo securement

- Coupling devices

- Driveshaft, exhaust, frame, fuel systems

- Lighting devices (headlamps, turn/tail/stop lamps)

- Steering, suspension, tires, wheels, windshield wipers

- Trailer and van body integrity

- Passenger-carrying vehicles:

Emergency exits, battery compartments, seating, electrical systems

Level II – Walk-Around Driver/Vehicle Inspection

Similar to Level I but without going under the vehicle. Includes all the driver-related checks and a visual-only vehicle inspection, such as:

- Brakes

- Cargo securement

- Tires, lights, wipers, exhaust

- Steering, suspension

- Vehicle inspection reports

This level is common during roadside stops or quick compliance checks.

Level III – Driver/Credential/Administrative Inspection

Focuses only on driver documentation and compliance and includes:

- Driver’s license

- Medical certificate and Skill Performance Evaluation (SPE) certificate

- HOS logs and records of duty status

- Driver Vehicle Inspection Reports (DVIR)

- Carrier identification

Mechanical violations are not included. This level is often used to verify driver readiness and compliance with administrative regulations.

Level IV – Special Inspection

Targeted, one-time DOT inspections. Conducted to investigate a specific issue, trend, or component, often part of a research study or regulatory focus. It is not routine and is usually done in response to previous violations or data analysis.

Level V – Vehicle-Only Inspection

A complete vehicle inspection without the driver present. This inspection includes all vehicle-related components covered in a Level I and can be conducted at the carrier’s facility or terminal.

Level VI – Enhanced NAS Inspection for Radioactive Material

Specialized for carriers transporting high-risk radiological cargo. Includes:

- Level I inspection items

- Additional radiological safety checks

- Strict compliance with radioactive material handling per 49 CFR 173.403

- Enhanced out-of-service criteria for HRCQ (Highway Route Controlled Quantities) of radioactive material

Level VII – Jurisdictional Mandated Inspection

Inspections outside federal standards, often state or local programs. Applies to:

- School buses

- Limousines

- Taxis

- Hotel shuttles

- Intrastate commercial vehicles

Each jurisdiction sets its own criteria and inspector training standards. These inspections do not qualify for a CVSA decal.

Level VIII – North American Standard Electronic Inspection

Remote, in-motion inspections done electronically with no human interaction. This inspection pulls data points such as:

- GPS location

- Driver ID and license status

- HOS and ELD records

- Medical certificate

- Vehicle registration

- DOT number

- UCR compliance

- Active out-of-service orders

This inspection happens while the vehicle is moving, using wireless data exchange technology, a growing trend in modern enforcement.

How Do DOT Inspections Affect Carriers?

DOT inspections directly impact a carrier’s CSA (Compliance, Safety, Accountability) scores, which are used by the FMCSA to evaluate safety performance.

High CSA scores, driven by frequent violations or out-of-service orders flag a carrier as high-risk. This can lead to more frequent inspections, DOT audits, higher insurance premiums, and even loss of business opportunities. Clients, insurers, and regulators all use CSA data to determine whether a carrier is safe and reliable.

Here are the top five driver and vehicle violations and the number of occurrences cited during roadside inspections so far in 2025:

2025 Top Driver Violations

- Failed to obey a traffic control device – 32,012

- ELD form and manner – 27,020

- Speeding 6-10 miles per hour over the speed limit – 26,61366

- Lane restriction violation – 21,460

- Operates a CMV and does not have a valid CDL – 19,289

2025 Top Vehicle Violations

- Operating a vehicle without documentation of a periodic inspection – 77,768

- Roto, Clamp, DD-3 or Bolt – 50,731

- Inoperable Required Lamp – 49, 795

- All others, leaking or inflation less than 50% of the maximum inflation pressure – 43,728

- Operating a CMV without proof of a periodic inspection – 29,702

How Can Carriers Prepare to Pass DOT Inspections?

Preparation starts long before an inspector arrives. Carriers who pass inspections consistently aren’t just “lucky”; they’ve put systems in place that prioritize compliance, training, and accountability long before an inspector shows up. Here’s how carriers can stay ahead:

- Train drivers on inspection protocols, proper documentation, and hours-of-service rules.

- Conduct regular vehicle maintenance and daily pre-trip inspections.

- Monitor MVRs continuously, to catch new violations, suspended CDLs or issues with medical cards.

- Keep all driver files up to date, including drug and alcohol tests, training records, and employment history.

- Establish clear policies for vehicle cleanliness, equipment checks, and driver compliance.

- Audit logs and records regularly to catch errors before inspectors do.

How Can Carriers Keep Up with New Inspection Data

Relying solely on the FMCSA portal to track inspection activity can be time-consuming, manual, and easy to overlook. Instead, carriers can leverage CSA Monitoring technology to simplify compliance and gain real-time visibility into their fleet’s safety performance.

CSA Monitoring pulls carriers FMCSA data directly from their USDOT number and alerts on new inspections, violations and DOT reportable crashes. Rather than digging through reports, carriers get a clear, organized view of their drivers and vehicles, making it easy to spot repeat offenders and common violations that may be impacting your safety scores.

Ready to take control of your FMCSA data? Learn how CSA Monitoring can give your team instant visibility into DOT violations, inspection results, and crash reports, before they impact your CSA score.

*We are not lawyers. Consult with your legal counsel to ensure your processes and procedures meet/ or exceed safety standards and compliance regulations. Please read our legal disclaimer.